As further described in a set of blogs S/Y Tossan is a self-built sailing catamaran by the design of the well-known multihull designer Kurt Hughes. The construction of the hulls and boat is based on a Kurt Hughes 48′ day charter design, in the US certified for 49 passengers and 2 crew members.

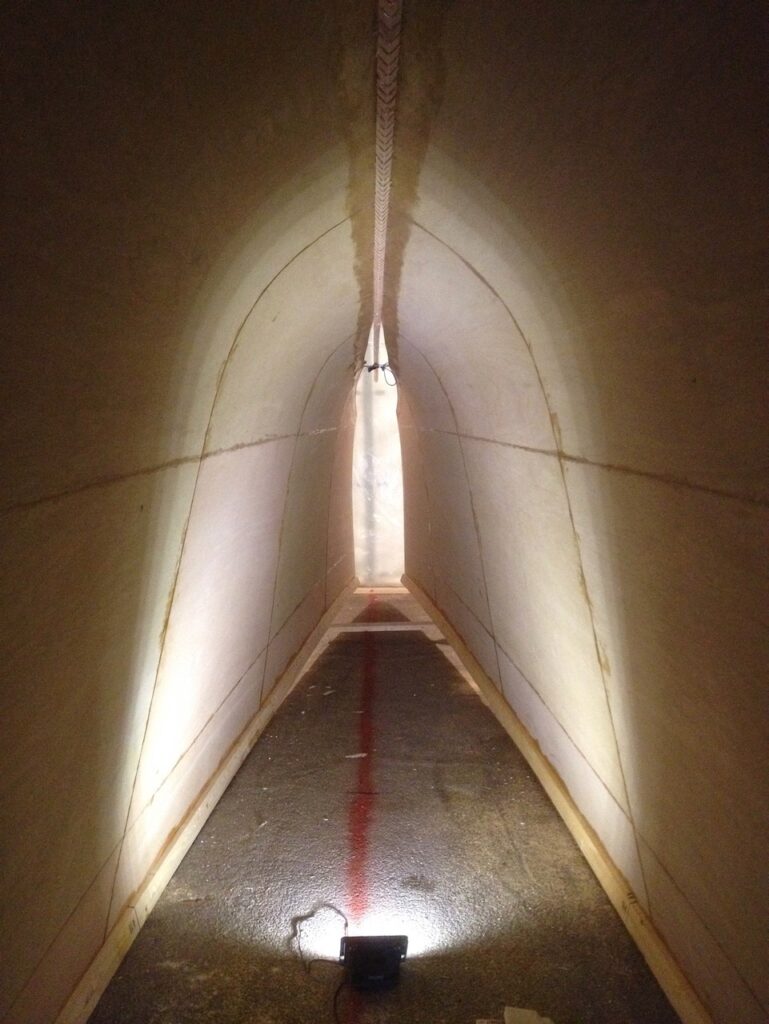

The construction methodology/philosophy used is the Gougeon Brothers’ West System, a well documented and used system for boat construction. The West System is an epoxy based construction methodology, well-used globally but primarily in the US many low number series-built or self-built boats. The hulls and entire construction is built in a controlled very low-humidity environment. Every piece of the construction is fully treated with epoxy to conserve the wood. In addition, all exterior surfaces are covered with a layer of glassfiber entirely covered with epoxy to guarantee the thickness of the exterior epoxy and provide additional mechanical protection. All reinforcements are made out of glassfiber and epoxy.

A very common construction and material in boats is plastic. This often refers to polyester which is a challenging material compared to epoxy given polyester absorbs and let through moist. The result is often encapsulated moist leading to rotten wood surfaces and construction failures. As per my father’s notes there is not a single drop of polyester, or Glassfiber Reinforced Polyester (GRP), onboard S/Y Tossan.

In regards to the plywood used in the sandwich construction (plywood/foam/plywood) it is entirely made up of so called Lauan plywood (also known as Lauanplywood, or Lauanply).

[…] lauan is a tropical wood and also has the same colors, uses, and many characteristics of genuine mahogany […] As plywood, it is used in sub-flooring and for backs, bottoms and drawers in furniture making. Red lauan has excellent waterproof properties making it especially popular for boat construction.

Dain’s lumber (2023-07-18)

Specification

- Design: Kurt Hughes 48′ day charter

- Construction methodology: Gougeon Brothers, West System

- Construction material, main components

- Plywood: Lauanplywood (material reference/description)

- 3.6 x 2440 x 1220 mm BB/CC (some 325 sheets, at least)

- 12 x 2440 x 1220 mm BB/CC (some 20 sheets, at least)

- Epoxy (from Hexion)

- Epidote Resin MSG LR 235 (480 kg, at least)

- Epicure Curing Agent LH 235 (150 kg, at least)

- Foam (from Jackon)

- Glass fibre (from Suter-Kunststoffe AG), examples

- Glasgewebe 92112 200 g/m2 (300 sqm, at least)

- Glasgewebe 92125 280 g/m2 (150 sqm, at least)

- Glasgewebe 91135 288 g/m2 (25 sqm, at least)

- Aluminium pipes (from Norrköpings Handelsstål)

- Aluminium pipe 6060 T6, 40 x 7.5 x 6000 mm (EN AW-6060 T6/66)

- Aluminium pipe 6082 T6, 150 x 10 x 6000 mm (EN AW-6082 T6)

- Acid proof welded pipe EN 1.4404 annealed 60.3 x 3.91 x 6000 mm (EN 1.4404)

- Additional material, lots of additional components

- Plywood: Lauanplywood (material reference/description)

- Construction: sandwich (plywood/foam/plywood, all covered in epoxy)

Antifouling

To protect the two hulls from organisms that can cause harm antifouling is used. It is a paint coating used to protect a boat’s hull(s), daggerboards, and rudders. The antifouling paint used on S/Y Tossan is copper based and very effective. The hulls need to be cleaned every now and then, and then papered to activate the copper in order to prevent growth of organisms on the hulls. This can be done while beaching.