With the shipyard ready for action it was time to get construction going. By this stage one has to realize the commitment and perseverence needed to build a full sailing catamaran from scratch. If you wonder, this requires a multi-year full-time commitment and a lot of competence. On the positive side, with do-it-yourself (DIY) projects is that you get it your way. Seeing the result of S/Y Tossan I can sign to that my father made it all the way, and achieved something great.

Think of DIY, and you probably imagine making and building things yourself — decorating or putting up shelves. But DIY goes far beyond home improvements. It isn’t so much a practical skill as a state of mind.

Science Museum, London (February 14, 2023)

Searching the web for DIY references there are a number of philosophies and do-it-yourself trends available. The quote from Science Museum in London is highly relevant stating DIY is a “state of mind”. I see this as an important dimension required to achieve DIY projects from start to finish. My father certainly had perseverence and commitment in what he did, the competence to do it, and the dream to fuel him.

Time to get going. Starting point; drawings, a pile of plywood and a few barrels of epoxy.

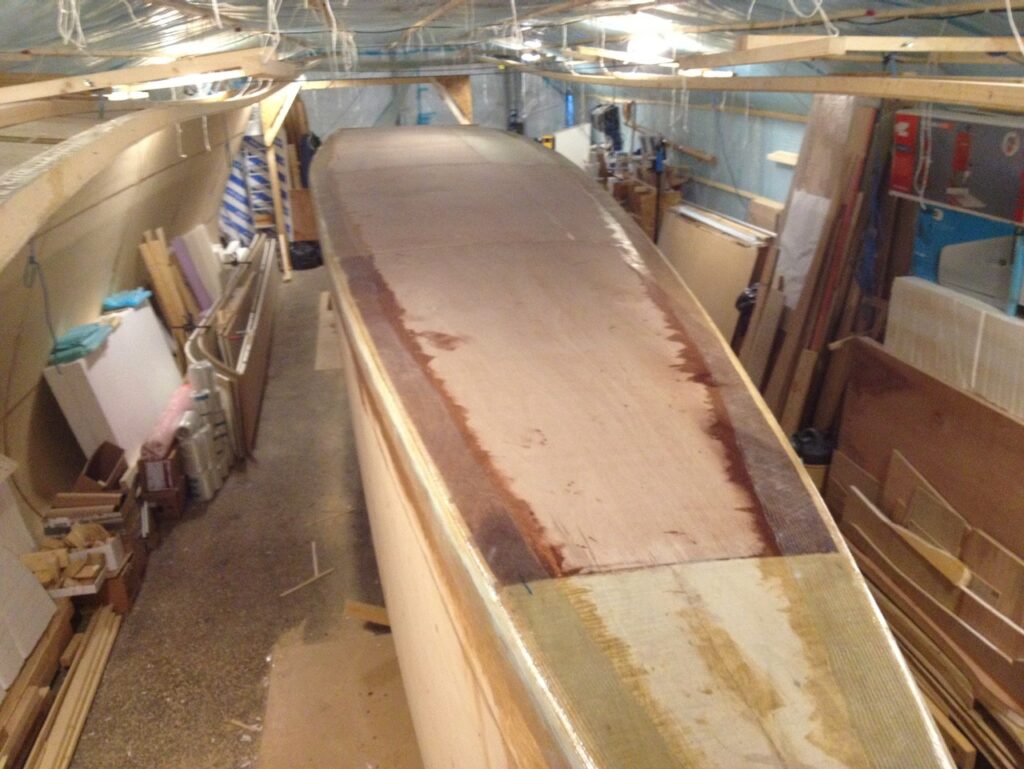

With the Kurt Hughes 48′ sailing catamaran drawings and design set, the early days of construction started. How to go about it? With a large construction and project like this you have to divide it into smaller parts, small enough to be achievable. In the case of S/Y Tossan each hull, and the beams connecting them were defined as separate sections.

For more information on materials used, building methodology and more please see the Hulls and construction section.

Production tools, molds, molds, and molds

For each section, based on the drawings, consequently you need to create molds. For each mold and material going in to the production you need production tools and preparations, e.g. a tool to shape each of the plywood sheets. The more I talked to my father I realized the amount of effort he put in, and the amount of planning to get things right.

Sections taking shape

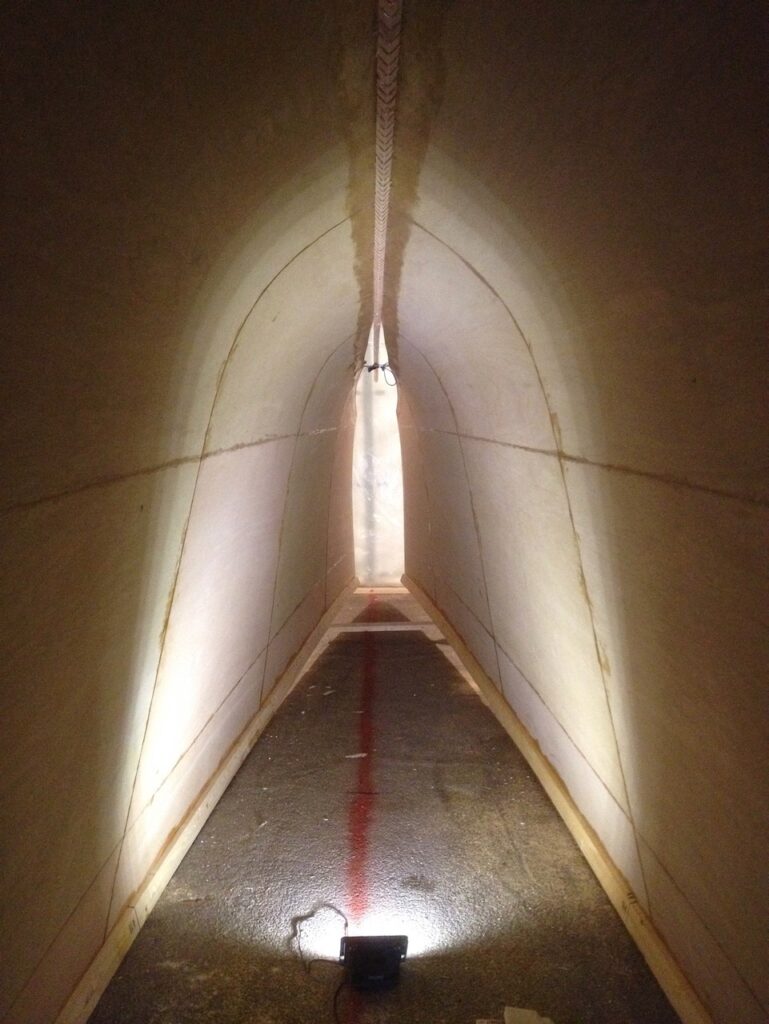

With molds built my father prepared the foundation for each section. Each hull of S/Y Tossan is 15 meters long, built up of sheets of plywood of 1.2 x 2.4 meters. With some simple math that makes up approxiamately 12-14 sheets per side of one hull. That makes a total of some 50 sheets of plywood, all carefully cut and glued together and then shaped using the molds. Given S/Y Tossan has a composite structure, a so called sandwich construction, each section has a plywood/cell foam/plywood combination all glued together with epoxy under high pressure.

With all the construction work done each section started to take shape. As sections completed they moved out from the tent and stored outside for the world to see.

Productions started in June 2014, continuing into 2015. By summer of 2016 two hulls, all beams and large sections stood outside waiting for the next move.

This post is clearly not describing all the details, all the energy, and the perseverence behind the full construction. Imagine the total effort. Would you be up for it?

Build or buy, that is the question.

As stated by the Science Museum in London, do-it-yourself cleary is a mindset. Are you considering to build your own catamaran? How about more quality time and jumping directly to a life on the ocean? S/Y Tossan is for sale. If you are keen to learn more please browse the webpage and reach out to book a tour or have any question answered.